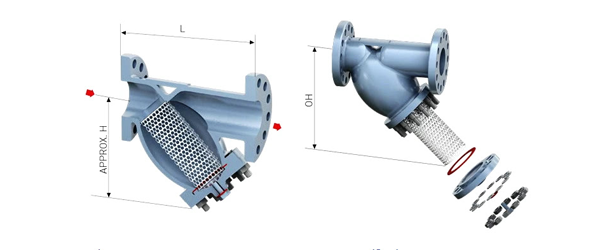

Cast Y-Strainer are available in most materials. Standard body materials offered are Cast Iron, Ductile Iron, Cast Steel, Stainless Steel, Chrome-Moly and Bronze. The Y-Strainer is equipped with a blow-off port. A ball valve can be fitted to flush debris that is easily removable from the screen and exhaust to atmosphere or a drain system. This feature allows for easy cleaning without interrupting the process. Various Perforations, Mesh or Perforation Mesh combinations or Wedge Wire screens are available to meet your process requirements.

- +968 98872735

- info@greensphereen.com

- Muscat, Oman

Instrumentation

Y-Strainer

Typical Specifications:

- Body Materials: Cast iron, ductile iron, carbon steel, stainless steel, bronze

- Screen Materials: Stainless steel (304, 316), Monel, or custom materials based on media

- Pressure Ratings:

- Up to 6,000 psi for high-pressure applications - Temperature Range: -29°C to +425°C (-20°F to +800°F), depending on materials

- Mesh Sizes: 10 to 400 mesh

- Sizes Available: From ¼" to 24" and larger

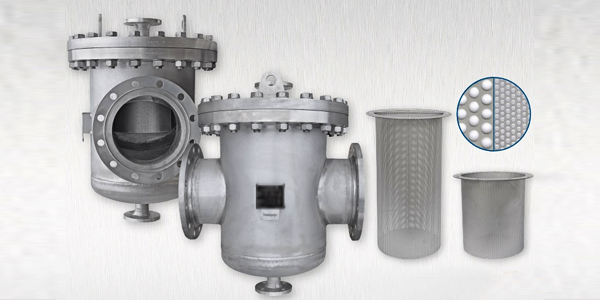

Basket Strainer

They are designed for applications where high volumes of solid contaminants are expected and where the clean-out will be habitually. For systems handling easily flushable solid, a modified cone bottom basket can be tiled and used in conjunction with a manual or automatic blow-down through a drain port, enabling this technique clean-out without removal of the screen, and without interrupting the process flow.

Typical Specifications:

- Body Materials: Stainless steel (304, 316), carbon steel, Monel, Hastelloy, duplex steel, or custom alloys

- Mesh Sizes: 20 to 400 mesh

- Perforation Sizes: Typically 1/32" to 1/2"

- Pressure Ratings:

- Can be designed to withstand full-line pressure temporarily - Temperature Range: -29°C to +425°C

- Sizes Available: ½" to 48" and larger

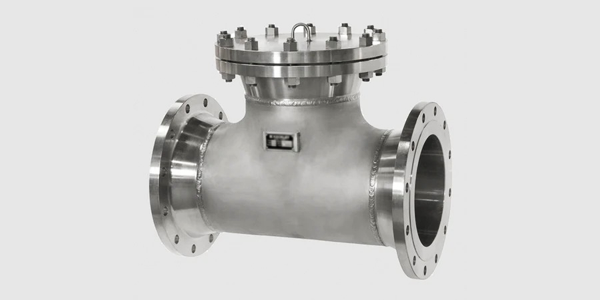

Tee Strainer

Tee Type Strainers are providing a cost-effective solution to large nominal bore straining requirements. They can be installed in both vertical and horizontal piping and also be configured for right-angled operations Tee strainers are commonly supplied with range of graded filtration levels from fine to coarse, or vice-versa—to ensure the system maintains the required cleanliness level under full-load conditions. They are available with either bolted covers or quick opening covers for application requirements. Tee strainers are used in applications that require compact and easily accessible strainers to protect pumps, valves, and other critical equipment.

Typical Specifications:

- Body Materials: Carbon steel, stainless steel (304, 316), alloy steel, duplex stainless steel

- Straining Element: Perforated or mesh-lined basket (removable), available in stainless steel or custom alloys

- Pressure Ratings:

- Custom designs available for higher pressure systems - Temperature Range: -29°C to +425°C , depending on materials and gasket selection

- Mesh Sizes: 20 to 400 mesh; perforations from 1/32" to ½" or custom

- Sizes Available: From 2" to 48"

Conical Strainers

Conical strainers are widely utilized in variety of fluid straining applications to safeguard downstream process system components in many industries. water handling applications, where very common in conical strainers which are used to protect equipment that could be damaged or clogged by unwanted materials such as sand or other debris.

In addition to steam applications, conical strainers are often used in air and natural gas systems. Here again, high operating pressures are not uncommon. However, unlike steam, high air pressure does not necessarily imply high temperature and so, ordinary carbon steel bodies of sufficient wall thickness are typically sufficient

Typical Specifications:

- Body Materials: Stainless steel (304, 316), carbon steel, Monel, Hastelloy, duplex steel, or custom alloys

- Mesh Sizes: 20 to 400 mesh

- Perforation Sizes: Typically 1/32" to 1/2"

- Pressure Ratings:

- Can be designed to withstand full-line pressure temporarily - Temperature Range: -29°C to +425°C

- Sizes Available: ½" to 48" and larger

Tube fittings

We provide international standard and certificate high pressure Tube fittings are used to connect, seal, and regulate the flow of fluids or gases in piping and tubing systems. They ensure leak-proof and secure connections between different segments of tubes, making them essential in industries like oil & gas, chemical processing, pharmaceuticals, food & beverage, and hydraulics. We offer wide range of materials like Carbon steel, SS, Brass etc., with size starting from 1/16” diameter and different connections of Male/Female, threaded, welded, or push-in.

Types of Tube Fittings:

- Compression Fittings

- Push-to-Connect Fittings

- Flare Fittings

- Bite-type Fittings

- Weld Fittings

- Threaded Fittings

- Quick-Connect Fittings

Ball Valve

We offer high-quality, high-performance ball valves designed to meet the diverse needs of global industries. Our extensive product range serves various sectors, including oil and gas, petrochemicals, water treatment, and more. Ball valves are essential for effectively controlling the flow of liquids and gases, ensuring safety, reliability, and operational efficiency in critical processes.

Manufactured using premium materials such as carbon steel, stainless steel, bronze, and special alloys, our ball valves are available in sizes up to 48 inches, with pressure ratings up to 6,000 psi and temperature ranges from -29°C to +260°C. Our commitment to innovation and strict quality control ensures that every product complies with international standards and consistently exceeds customer expectations.

Valve Type:

- Two-piece or three-piece body

- Full port (full bore) or reduced port

- Floating or trunnion-mounted ball

- Manual, gear-operated, or actuated (electric/pneumatic)

- Fire-safe or anti-static designs (for hazardous areas)

Needle valve

Our needle valves are designed to provide precise control of fluid flow, allowing for fine adjustments in various applications. They are especially effective in low-flow scenarios, offering exceptional flow regulation accuracy. Built to perform under the harshest conditions, including high pressure, extreme temperatures, and high-vibration environments, these valves ensure reliable operation in demanding systems.

Available in sizes ranging from 1/8 inch to 1 inch with compression end connections, our needle valves are constructed from durable materials such as stainless steel, carbon steel, bronze, and special alloys. They are rated for pressures up to 10,000 psi and can withstand temperatures ranging from -54°C to +500°C.

Valve Type:

- Straight type

- Angle type

- Union bonnet or screwed bonnet

- Integral bonnet (for compact design)

- Block & bleed needle valve (single or double isolation)

Check Valve

Our check valves are engineered in accordance with international standards to allow unidirectional fluid flow while preventing backflow, thereby safeguarding pumps and drive motors from potential damage. These valves are rated for high pressure applications up to 10,000 psi. We offer a wide range of sizes, from ½ inch to 48 inches, constructed from materials such as carbon steel, stainless steel, brass, and various special alloys. They are suitable for operating temperatures ranging from -50°C to 600°C.

Valve Type:

- Swing check valve

- Lift check valve

- Ball check valve

- Dual plate (wafer type) check valve

- Tilting disc check valve

- Spring-loaded inline check valve

- Non-slam check valve

Gauge root valve

Valve Type:

- Single isolation

- Isolation with bleed (2-valve configuration)

- Block & bleed valve

- With or without test/drain port

- Angle or straight pattern

Relief valve

Valve Type:

- Spring-loaded relief valve

- Pilot-operated relief valve

- Thermal relief valve (for liquid expansion)

- Gas, steam, or liquid service types