Depending on the specific application, surfaces can be further protected using Ceramic-Metal Surfacing Coating or Ceramic-Metal Ultra Flow, a self-leveling, high-performance coating designed for industrial environments.

Engineered with Nano Molecular Bonding Technology, these coatings offer superior adhesion and creep resistance, ensuring long-lasting protection under extreme conditions.

- +968 98872735

- info@greensphereen.com

- Muscat, Oman

Coatings

Green Sphere Energy LLC

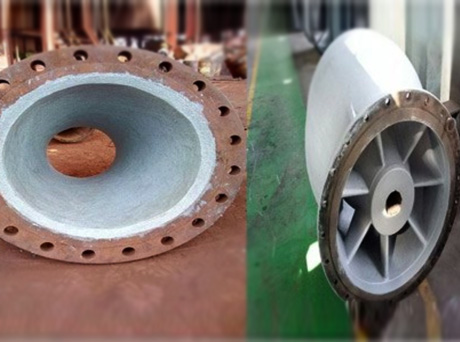

Protective Overcoat with Ceramic-Metal Surface Coatings

Key Features:

- Exceptional resistance to abrasion, cavitation, erosion, and corrosion

- High resistance to a broad range of chemicals

- Prevents bi-metallic corrosion and structural degradation

- Reinforced with Silicon-Steel alloy for enhanced mechanical strength

- Provides a durable, smooth, and highly protective finish

- Designed for long-term performance in demanding applications

Applications Include:

- Condensers: Tube sheets, water boxes, and end covers

- Cooling and Condensate Systems Pumps: Centrifugal, turbine, and vacuum systems

- Flow Components: Valves, flanges, elbows, T-pieces, impellers, and propellers

- Industrial Equipment: Heat exchangers, tanks, process vessels, and gas scrubbers

Green Sphere Energy LLC

Surface Protection with Advanced Ceramic-Metal Coating Technology

Surfaces affected by abrasion, erosion, or corrosion can be effectively restored and protected using advanced ceramic-metal composite repair systems. These coatings offer exceptional resistance not only to erosion and corrosion but also to impingement, cavitation, entrained particles, and bi-metallic corrosion.

Incorporating nano-molecular bonding technology, the coating delivers superior adhesion and resistance to mechanical stress, ensuring long-term durability.

Key Features:

- Outstanding resistance to abrasion, erosion, and corrosion

- High chemical resistance across a wide range of aggressive substances

- Nano-ceramic fillers enhance surface hardness and wear resistance

- Silicon-steel alloy improves the mechanical strength of the coating

- Nano fillers create an ultra-smooth, abrasion-resistant finish, promoting efficient fluid flow ("roll-round" effect)

- Easy application with a short-bristle brush or roller

- Designed for extended service life

- Typical Applications

- Centrifugal, turbine, and vacuum pump components

- New and in-service equipment exposed to harsh environments

- Pump casings, impellers, and fan blades

- Heat exchangers, tube sheets, and water circulation systems

- Abrasion-resistant lining for butterfly and gate valves

- Internal surfaces of tanks and process vessels

- Gas scrubbers and similar industrial equipment